Production facilities are seamlessly integrated into Industry 4.0 networks, using image recognition and bus interfaces, complemented by Industry 4.0 technologies such as MQTT, OPC UA, and REST APIs, without the need for hardware modifications.

Supplementary hardware, based on Artificial Intelligence (AI) and image recognition, is utilized to effectively read out sensors and instruments that are not directly connected to the PLC (Programmable Logic Controller). This technology enables the collection of valuable data from systems that were previously not digitally accessible.

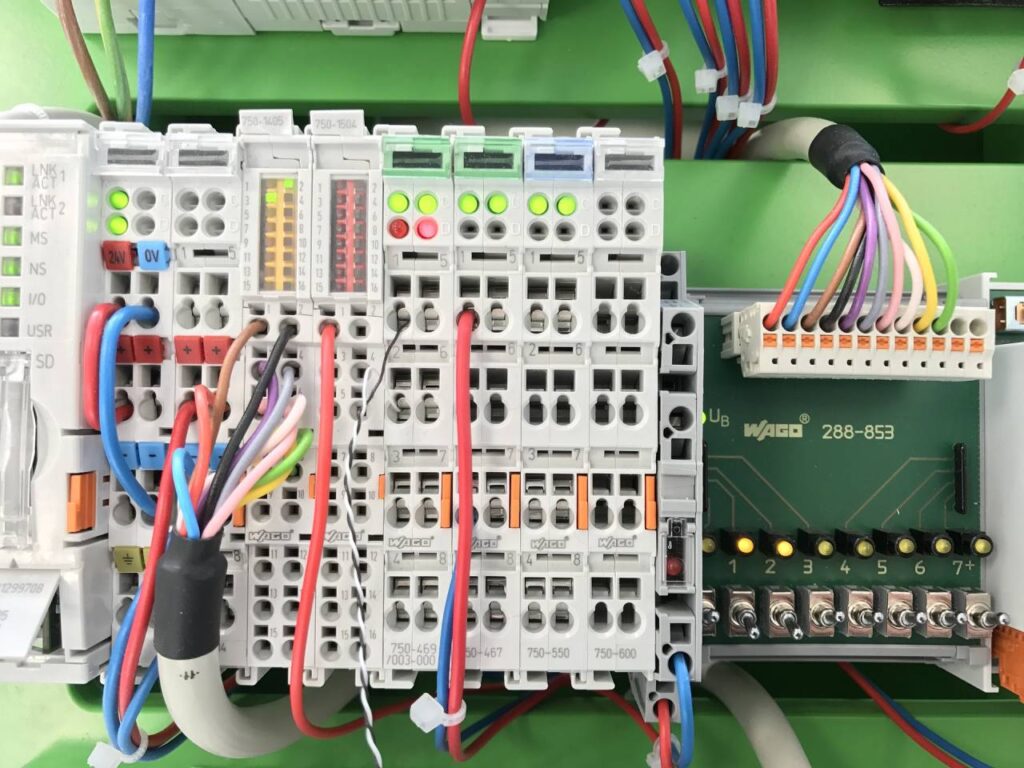

In parallel, bus interfaces are used to directly read out metrics already integrated into the PLC, such as batch numbers and production cycles. Through these interface cards, existing PLC systems can be seamlessly incorporated into modern Industry 4.0 networks, without the need to renew the PLC hardware.

My motivation for this business idea lies in the belief that the future of the manufacturing industry is in intelligent digitalization and networking. I am committed to making production processes more efficient, flexible, and sustainable. By integrating existing production facilities into Industry 4.0 networks, without the need for costly and environmentally harmful hardware upgrades, I see an opportunity to achieve both ecological and economic goals.

My vision is to make a significant contribution to Industry 4.0 by offering solutions that enable companies to modernize their production facilities in an environmentally friendly and cost-effective way. I strive to design production technology in a way that not only meets economic requirements but also has a positive impact on the environment. In this vision, I see a symbiosis of technological innovation and sustainable development, ultimately contributing to creating a smarter and greener future for the manufacturing industry.

The solution aims to extend the lifespan of machines by efficiently integrating existing systems into modern Industry 4.0 networks. This is achieved without the need for costly and time-consuming hardware upgrades, leading to a significant reduction in downtime, as the production processes can continue uninterrupted during the integration.

The idea addresses the problem of resource wastage in the industrial and electronics sector by preventing fully functional plants and machines from being unnecessarily equipped with new PLC systems. This not only saves resources but also avoids increased costs and production interruptions that can arise from retrofitting.

GRemote VisionAI: An AI-powered camera module for capturing and reading analog and digital displays.

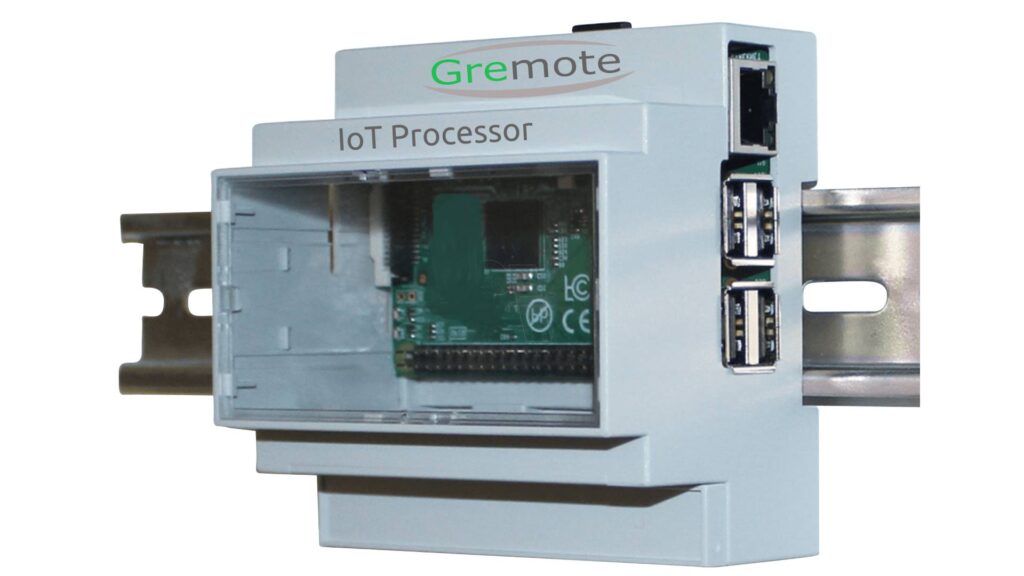

GRemote IoT Processor: An IoT-embedded PC that processes data from VisionAI and integrates it into IoT structures (MQTT, OPC UA, REST APIs).

GRemote BUSConnector: A PC with an interface card for feeding data from older PLCs into modern IoT structures.

In addition to the products, GRemote offers services for setup, maintenance, and IT security to ensure seamless integration and continuous system optimization. This combination of innovative hardware and professional service positions GRemote as a complete provider for the modernization of production facilities in the Industry 4.0 environment.

( VisionAI 3dview)

A key advantage of this method is that the integration of Industry 4.0 solutions does not require any changes to the hardware of the facilities, thereby ensuring compliance with equipment guidelines and operating permits. There are no legal or safety concerns, as the physical structure and safety functions of the machines remain unaffected.

For the planned business, North Rhine-Westphalia (NRW) and the Euregio in Aachen are ideal locations. The central location in Europe makes it easy to reach and serve customers throughout Europe. The excellent infrastructure with highways, railroads, and airports facilitates the transport of goods and access to international markets. NRW also offers a high availability of skilled workers and an excellent educational landscape, which strengthens innovation capacity.

The Euregio in Aachen, bordering Belgium and the Netherlands, opens up cross-border business opportunities. Proximity to these countries facilitates access to various markets and promotes international cooperation.

Overall, the locational advantages of NRW and the Euregio in Aachen offer optimal conditions for the company to grow efficiently, serve customers across Europe, and develop innovative solutions in an international environment

Contact

Questions / Suggestions Please give me a quick call at +491638731552 or send an email to Start(at)Verkooyen.org. You are also welcome to use the contact form on Verkooyen.org.